Partner with FleetCrew to Manage your CARB Diesel Compliance Program

Avoid costly compliance violations due to California's new Diesel Heavy Duty I/M Clean Truck Check Regulations

As CARB Compliance Experts, FleetCrew provide a comprehensive solution to manage fleet compliance, stress-free

Stop stressing over CARB'S complex compliance regulations

Reduce inspection costs, streamline processes and mitigate risks

Painlessly obtain Truck Certificates and renew DMV registrations

Avoid costly compliance violations & fines

Stop stressing over CARB'S complex compliance regulations

Reduce inspection costs, streamline processes and mitigate risks

Painlessly obtain Truck Certificates and renew DMV registrations

Avoid costly compliance violations & fines

California's Air Resource Board's (CARB) new Heavy Duty Inspection and Maintenance Program (HD I/M Clean Truck Check i.e., "smog check") will impact every diesel truck coming in and out of California starting on January 1, 2024.

Are you ready for 2024?

Are you prepared for increased CARB scrutiny and enforcement geared to penalize polluters and poorly maintained trucks? It's time to prove it or lose it! Enforcement is no longer catch me if you can.

Are you prepared for increased CARB scrutiny and enforcement geared to penalize polluters and poorly maintained trucks? It's time to prove it or lose it! Enforcement is no longer catch me if you can.

Able to understand and navigate the complexities of the new Inspection and Maintenance regulations?

Able to understand and navigate the complexities of the new Inspection and Maintenance regulations?

Have the staff and systems to record, maintain, track and quickly access every inspection and compliance task for each truck?

Have the staff and systems to record, maintain, track and quickly access every inspection and compliance task for each truck?

Prepared with a personalized maintenance and repair plan to proactively protect you from costly compliance violations?

Prepared with a personalized maintenance and repair plan to proactively protect you from costly compliance violations?

Secured relationships with repair facilities with expertise in resolving complex fault code issues?

Secured relationships with repair facilities with expertise in resolving complex fault code issues?

Are you prepared for increased CARB scrutiny and enforcement geared to penalize polluters and poorly maintained trucks? It's time to prove it or lose it! Enforcement is no longer catch me if you can.

Are you prepared for increased CARB scrutiny and enforcement geared to penalize polluters and poorly maintained trucks? It's time to prove it or lose it! Enforcement is no longer catch me if you can.

Able to understand and navigate the complexities of the new Inspection and Maintenance regulations?

Able to understand and navigate the complexities of the new Inspection and Maintenance regulations?

Have the staff and systems to record, maintain, track and quickly access every inspection and compliance task for each truck?

Have the staff and systems to record, maintain, track and quickly access every inspection and compliance task for each truck?

Prepared with a personalized maintenance and repair plan to proactively protect you from costly compliance violations?

Prepared with a personalized maintenance and repair plan to proactively protect you from costly compliance violations?

Secured relationships with repair facilities with expertise in resolving complex fault code issues?

Secured relationships with repair facilities with expertise in resolving complex fault code issues?

FleetCrew Makes the Complicated Simple

Reduce your stress

You just want to run your business and keep your fleet on the road making money. The last thing you want is for your company to be labeled as a flagrant air polluter.

The new CARB compliance regulations are complex with extensive record-keeping requirements that make it grueling to keep your fleet compliant.

As CARB compliance experts for over 20 years, FleetCrew uses our IQ proprietary software system to help you efficiently manage compliance records and reporting so you keep your trucks running with less stress.

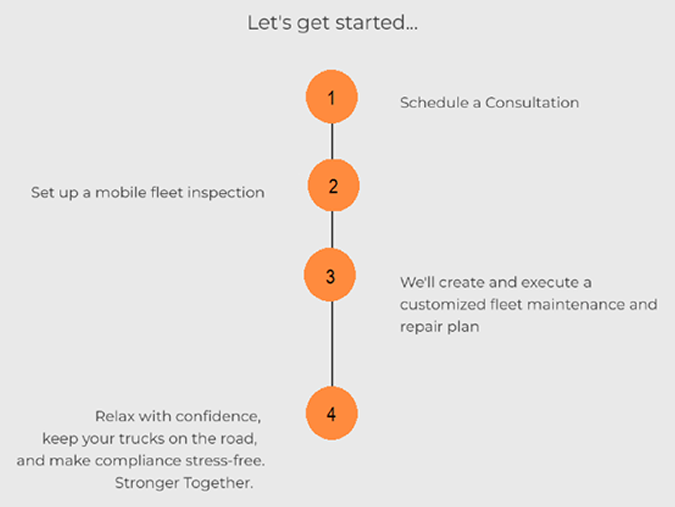

Schedule a Consultation

You just want to run your business and keep your fleet on the road making money. The last thing you want is for your company to be labeled as a flagrant air polluter.

The new CARB compliance regulations are complex with extensive record-keeping requirements that make it grueling to keep your fleet compliant.

As CARB compliance experts for over 20 years, FleetCrew uses our IQ proprietary software system to help you efficiently manage compliance records and reporting so you keep your trucks running with less stress.

Reduce your stress

You just want to run your business and keep your fleet on the road making money. The last thing you want is for your company to be labeled as a flagrant air polluter.

The new CARB compliance regulations are complex with extensive record-keeping requirements that make it grueling to keep your fleet compliant.

As CARB compliance experts for over 20 years, FleetCrew uses our IQ proprietary software system to help you efficiently manage compliance records and reporting so you keep your trucks running with less stress.

Schedule a Consultation

You just want to run your business and keep your fleet on the road making money. The last thing you want is for your company to be labeled as a flagrant air polluter.

The new CARB compliance regulations are complex with extensive record-keeping requirements that make it grueling to keep your fleet compliant.

As CARB compliance experts for over 20 years, FleetCrew uses our IQ proprietary software system to help you efficiently manage compliance records and reporting so you keep your trucks running with less stress.

Partner with FleetCrew's Expertise

Say goodbye to these stressful tasks.

FleetCrew's comprehensive "GRIT" proprietary solution takes the headache out of managing fleet compliance

G

enerate records to register and report vehicles

Educate you on how the compliance regulations apply specifically to your fleet

Educate you on how the compliance regulations apply specifically to your fleet

Register all trucks in the CARB reporting system

Register all trucks in the CARB reporting system

Personalize all fleet contacts for various repair responsibilities (accountabilities)

Personalize all fleet contacts for various repair responsibilities (accountabilities)

Enter all vehicles into FleetCrew IQ software

Enter all vehicles into FleetCrew IQ software

Educate you on how the compliance regulations apply specifically to your fleet

Educate you on how the compliance regulations apply specifically to your fleet Register all trucks in the CARB reporting system

Register all trucks in the CARB reporting system Personalize all fleet contacts for various repair responsibilities (accountabilities)

Personalize all fleet contacts for various repair responsibilities (accountabilities) Enter all vehicles into FleetCrew IQ software

Enter all vehicles into FleetCrew IQ software

R

epair and communication plan

Connect by truck by location and develop inspections plans

Connect by truck by location and develop inspections plans

Inspect vehicles and develop a repair plan for fleet.

Inspect vehicles and develop a repair plan for fleet.

Options: Done for you, Do it yourself, or Hybrid model using in-house or third-party vendors.

Establish key contact accountability information for repair execution

Establish key contact accountability information for repair execution

Create digital records by truck to track and monitor every compliance task

Create digital records by truck to track and monitor every compliance task

Maintain closed-loop communication process for every truck repair

Maintain closed-loop communication process for every truck repair

Connect by truck by location and develop inspections plans

Connect by truck by location and develop inspections plans Inspect vehicles and develop a repair plan for fleet.

Inspect vehicles and develop a repair plan for fleet.Options: Done for you, Do it yourself, or Hybrid model using in-house or third-party vendors.

Establish key contact accountability information for repair execution

Establish key contact accountability information for repair execution Create digital records by truck to track and monitor every compliance task

Create digital records by truck to track and monitor every compliance task Maintain closed-loop communication process for every truck repair

Maintain closed-loop communication process for every truck repair

I

nspect

Collect and audit diagnostic files required for CARB submission

Collect and audit diagnostic files required for CARB submission

Follow up on repair delays and communicate with CARB for deadline extensions

Follow up on repair delays and communicate with CARB for deadline extensions

Ensure every truck repair is properly documented

Ensure every truck repair is properly documented

Collect and audit diagnostic files required for CARB submission

Collect and audit diagnostic files required for CARB submission Follow up on repair delays and communicate with CARB for deadline extensions

Follow up on repair delays and communicate with CARB for deadline extensions Ensure every truck repair is properly documented

Ensure every truck repair is properly documented

T

ruck Certificate (HD I/M Clean Truck Check Compliance Certificate)

Submit files to CARB, track and manage until approved

Submit files to CARB, track and manage until approved

Receive and file truck certificates and renew DMV registration

Receive and file truck certificates and renew DMV registration

Schedule next inspection and repeat bi-annually for the first 2 years, then quarterly every year thereafter

Schedule next inspection and repeat bi-annually for the first 2 years, then quarterly every year thereafter

Submit files to CARB, track and manage until approved

Submit files to CARB, track and manage until approved Receive and file truck certificates and renew DMV registration

Receive and file truck certificates and renew DMV registration Schedule next inspection and repeat bi-annually for the first 2 years, then quarterly every year thereafter

Schedule next inspection and repeat bi-annually for the first 2 years, then quarterly every year thereafter

G

enerate records to register and report vehicles

Educate you on how the compliance regulations apply specifically to your fleet

Educate you on how the compliance regulations apply specifically to your fleet

Register all trucks in the CARB reporting system

Register all trucks in the CARB reporting system

Personalize all fleet contacts for various repair responsibilities (accountabilities)

Personalize all fleet contacts for various repair responsibilities (accountabilities)

Enter all vehicles into FleetCrew IQ software

Enter all vehicles into FleetCrew IQ software

Educate you on how the compliance regulations apply specifically to your fleet

Educate you on how the compliance regulations apply specifically to your fleet Register all trucks in the CARB reporting system

Register all trucks in the CARB reporting system Personalize all fleet contacts for various repair responsibilities (accountabilities)

Personalize all fleet contacts for various repair responsibilities (accountabilities) Enter all vehicles into FleetCrew IQ software

Enter all vehicles into FleetCrew IQ software

R

epair and communication plan

Connect by truck by location and develop inspections plans

Connect by truck by location and develop inspections plans

Inspect vehicles and develop a repair plan for fleet.

Inspect vehicles and develop a repair plan for fleet.

Options: Done for you, Do it yourself, or Hybrid model using in-house or third-party vendors.

Establish key contact accountability information for repair execution

Establish key contact accountability information for repair execution

Create digital records by truck to track and monitor every compliance task

Create digital records by truck to track and monitor every compliance task

Maintain closed-loop communication process for every truck repair

Maintain closed-loop communication process for every truck repair

Connect by truck by location and develop inspections plans

Connect by truck by location and develop inspections plans Inspect vehicles and develop a repair plan for fleet.

Inspect vehicles and develop a repair plan for fleet.Options: Done for you, Do it yourself, or Hybrid model using in-house or third-party vendors.

Establish key contact accountability information for repair execution

Establish key contact accountability information for repair execution Create digital records by truck to track and monitor every compliance task

Create digital records by truck to track and monitor every compliance task Maintain closed-loop communication process for every truck repair

Maintain closed-loop communication process for every truck repair

I

nspect

Collect and audit diagnostic files required for CARB submission

Collect and audit diagnostic files required for CARB submission

Follow up on repair delays and communicate with CARB for deadline extensions

Follow up on repair delays and communicate with CARB for deadline extensions

Ensure every truck repair is properly documented

Ensure every truck repair is properly documented

Collect and audit diagnostic files required for CARB submission

Collect and audit diagnostic files required for CARB submission Follow up on repair delays and communicate with CARB for deadline extensions

Follow up on repair delays and communicate with CARB for deadline extensions Ensure every truck repair is properly documented

Ensure every truck repair is properly documented

T

ruck Certificate (HD I/M Clean Truck Check Compliance Certificate)

Submit files to CARB, track and manage until approved

Submit files to CARB, track and manage until approved

Receive and file truck certificates and renew DMV registration

Receive and file truck certificates and renew DMV registration

Schedule next inspection and repeat bi-annually for the first 2 years, then quarterly every year thereafter

Schedule next inspection and repeat bi-annually for the first 2 years, then quarterly every year thereafter

Submit files to CARB, track and manage until approved

Submit files to CARB, track and manage until approved Receive and file truck certificates and renew DMV registration

Receive and file truck certificates and renew DMV registration Schedule next inspection and repeat bi-annually for the first 2 years, then quarterly every year thereafter

Schedule next inspection and repeat bi-annually for the first 2 years, then quarterly every year thereafter

Words of Praise from Our Clients

FleetCrew is always there for us, getting our vehicles up and running right away. We are very happy with their complete compliance and emission maintenance service.

We've worked with FleetCrew for the past four years, FleetCrew make our CARB reporting a breeze. I would never use another company to ensure we are California compliant.

We've worked with FleetCrew for over 15 years, the service and dedication to our needs and expectations are top notch!! The response to our concerns and service calls are #1 and the technicians are very knowledgeable. FleetCrew has been a great partner in emissions compliance. As our fleet has grown over the years, FleetCrew has remained committed and has become, what we feel, is the best in California. We look forward to future years working with FleetCrew for seamless emissions compliance.

FleetCrew is always there for us, getting our vehicles up and running right away. We are very happy with their complete compliance and emission maintenance service.

FleetCrew is always there for us, getting our vehicles up and running right away. We are very happy with their complete compliance and emission maintenance service.

We've worked with FleetCrew for the past four years, FleetCrew make our CARB reporting a breeze. I would never use another company to ensure we are California compliant.

We've worked with FleetCrew for the past four years, FleetCrew make our CARB reporting a breeze. I would never use another company to ensure we are California compliant.

We've worked with FleetCrew for over 15 years, the service and dedication to our needs and expectations are top notch!! The response to our concerns and service calls are #1 and the technicians are very knowledgeable. FleetCrew has been a great partner in emissions compliance. As our fleet has grown over the years, FleetCrew has remained committed and has become, what we feel, is the best in California. We look forward to future years working with FleetCrew for seamless emissions compliance.

We've worked with FleetCrew for over 15 years, the service and dedication to our needs and expectations are top notch!! The response to our concerns and service calls are #1 and the technicians are very knowledgeable. FleetCrew has been a great partner in emissions compliance. As our fleet has grown over the years, FleetCrew has remained committed and has become, what we feel, is the best in California. We look forward to future years working with FleetCrew for seamless emissions compliance.

FleetCrew is always there for us, getting our vehicles up and running right away. We are very happy with their complete compliance and emission maintenance service.

We've worked with FleetCrew for the past four years, FleetCrew make our CARB reporting a breeze. I would never use another company to ensure we are California compliant.

We've worked with FleetCrew for over 15 years, the service and dedication to our needs and expectations are top notch!! The response to our concerns and service calls are #1 and the technicians are very knowledgeable. FleetCrew has been a great partner in emissions compliance. As our fleet has grown over the years, FleetCrew has remained committed and has become, what we feel, is the best in California. We look forward to future years working with FleetCrew for seamless emissions compliance.

FleetCrew is always there for us, getting our vehicles up and running right away. We are very happy with their complete compliance and emission maintenance service.

FleetCrew is always there for us, getting our vehicles up and running right away. We are very happy with their complete compliance and emission maintenance service.

We've worked with FleetCrew for the past four years, FleetCrew make our CARB reporting a breeze. I would never use another company to ensure we are California compliant.

We've worked with FleetCrew for the past four years, FleetCrew make our CARB reporting a breeze. I would never use another company to ensure we are California compliant. We've worked with FleetCrew for over 15 years, the service and dedication to our needs and expectations are top notch!! The response to our concerns and service calls are #1 and the technicians are very knowledgeable. FleetCrew has been a great partner in emissions compliance. As our fleet has grown over the years, FleetCrew has remained committed and has become, what we feel, is the best in California. We look forward to future years working with FleetCrew for seamless emissions compliance.

We've worked with FleetCrew for over 15 years, the service and dedication to our needs and expectations are top notch!! The response to our concerns and service calls are #1 and the technicians are very knowledgeable. FleetCrew has been a great partner in emissions compliance. As our fleet has grown over the years, FleetCrew has remained committed and has become, what we feel, is the best in California. We look forward to future years working with FleetCrew for seamless emissions compliance.

Don't risk vehicle compliance violations

that disrupt your business and cost your company substantial time and money to fix.

Get ahead of the curve.

Partner with FleetCrew to manage your fleet compliance and keep your trucks on the road making money.

that disrupt your business and cost your company substantial time and money to fix.

Get ahead of the curve.

Partner with FleetCrew to manage your fleet compliance and keep your trucks on the road making money.

Join us for a free webinar:

"Keep your fleet on the road with a clear roadmap to navigate California's new Heavy-Duty Inspection and Maintenance Program (HDIM) Regulations."

"Keep your fleet on the road with a clear roadmap to navigate California's new Heavy-Duty Inspection and Maintenance Program (HDIM) Regulations."

Join us for a free webinar

"Keep your fleet on the road with a clear roadmap to navigate California's new Heavy-Duty Inspection and Maintenance Program (HDIM) Regulations."